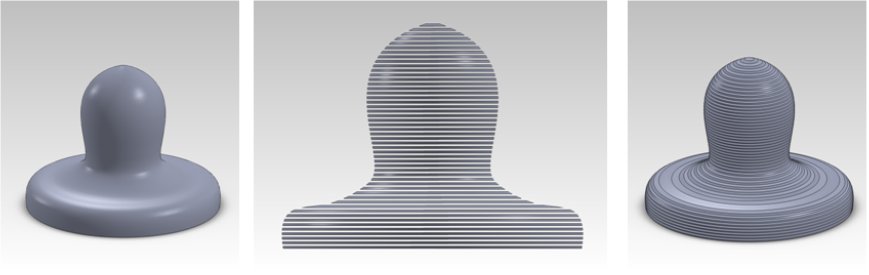

Additive manufacturing (AM) is the set of manufacturing technologies that create a product by addition of raw material using various principles. The process of addition is usually performed by deposition of plane layers, which represent cross-sections of the product, from the bottom to the top of the product, as shown in the following picture:

|

|

3D model of an object (left) Sliced representation of the object (center), and the object manufactured by AM (right)

Since the representation of an object by its sliced model requires calculation of huge number of its cross-sections, the process of creation of the sliced model is performed by computer. The huge number of layers means in the same time that the process of production and joining of the layers must be also controlled by a computer, so the complete additive manufacturing process is performed by computer. Depending on the material and the principle that is used for creation of the individual layers, and on the method used for the joining of the layers, there are several AM technologies, shown in the following table:

|

Name |

Raw material |

|

|

Stereolithography (SLA) |

Liquid photo-polymers |

1984‑1986 |

|

Selective laser sintering (SLS )/Direct Metal Laser Sintering (DMLS)/Selective laser melting (SLM) |

Plastic or metal powders |

1986‑1988 |

|

Fused deposition modeling (FDM) |

Filaments of polymers |

1989 |

|

Laminated object manufacturing (LOM) |

Sheets of paper and plastic material |

1991 |

|

Inkjet / polyjet |

Liquid photo-polymers |

1999 |

|

3D printing (3DP) |

Plastic or ceramic powder |

1997 |

|

Electron beam melting (EBM) |

Titanum alloy powder |

2003 |

The key advantages of the additive manufacturing technologies are:

- NO LIMITS TO SHAPE OF THE PRODUCT!

- fast preparation for the production process

- the same equipment is used for all products

- absence of human work during manufacturing process

- ability to completely automate the whole manufacturing process

- efficient use of the material

The key disadvantages of the additive manufacturing technologies are:

- slow speed of the manufacturing process

- limitations of shape of the products

- expensive machines that process metal

- limited dimensions of the products

- limited set of materials that may be processed by one machine

The most important advantage of the additive manufacturing technologies is that they enable manufacturing of complex shapes, with curved surfaces and empty internal spaces. It means that the application of the additive manufacturing is justified for manufacturing of expensive products with high value, like lightweight parts in automotive and aerospace industry, then the implants for human body in medical and dental applications etc. The applications where additive manufacturing is used for production of products for end-users are called Rapid Manufacturing.

|

Rapid Manufacturing – Lightweight component for automotive industry |

Rapid Manufacturing – Lightweight component for aerospace industry |

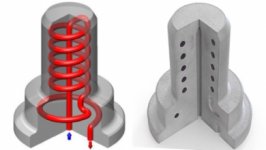

On the other hand, if the additive manufacturing is used to manufacture complex (and always expensive) tools for manufacturing by other technologies, these applications of additive manufacturing are called Rapid Tooling.

|

Rapid Tooling – 3D model and a section of an injection moulding tool with advanced cooling system |

However, in the most of the contemporary cases, the key advantage of the additive manufacturing (that justifies it high costs) is the short time needed to prepare the production, because the production process does not to be customized to the product. For that reason, the additive manufacturing is today almost exclusively used for production of prototypes during development of products, and such applications of the additive manufacturing are called Rapid Prototyping.

|

Rapid Prototyping – Several variants of the same product |

Unlike the subtractive and formative manufacturing, which are developed since the dawn of the mankind, the additive manufacturing is, essentially, the child of the XXI century. The reason is that additive manufacturing was not possible without computer. The application of the additive manufacturing is still seldom outside certain specific applications, and the unique potentials of these technologies still wait to be unlocked. Nevertheless, the additive manufacturing principle is the slow but overwhelming principle of building of the Nature itself – think of pearls, wood and mountains for example.

|

|

|

|

|

Nature – The Ultimate Additive Manufacturer |

||

The additive manufacturing has unique possibilities: due to the facts that one machine may make variety of products without requirement for skill workers, it looks as a perfect choice for manufacturing technology to be used in spaceships for interplanetary or even interstellar flights. If the subtractive technologies raised humanity from animal kingdom and if the formation technologies helped it to conquer the Earth, it does not require too much imagination to assume that additive manufacturing might be the technology that will bring humanity to Space.

Still staying on the Earth, the additive manufacturing has potential to transform the present business models of product development and manufacturing. As first, the ability to customize product for each individual user will certainly increase the role of product designers. Besides, the absence of need for qualified workers already led to development of additive manufacturing companies who do not have their product – additive manufacturing production is essentially a service! Extension of the concept leads to another business concept, “production from home”, where design is the service that is provided to the end-user. However, such possibility of manufacturing of high-tech products without possession of specific equipment and specific knowledge may also represent a threat, because it is easy to imagine production of weapons or other controlled goods by additive manufacturing.

Nevertheless, it is certain that additive manufacturing is one of the key challenges of XXI century, and that it deserves all attention of the academics and engineers. For many reasons, the research about the additive manufacturing technologies have to be public and open to control of the society.