Behind the design of any product are years and ages of engineering experience, and the experience is transformed in science that is studied in engineering courses. However, in everyday work of industrial and mechanical designers there is no time for scientific studies for each of the designed products. Therefore, the designers use design rules that tell them how to design certain properties of the products to meet the requirements of end users. The design rules represent condensed expressions of engineering knowledge and practice, which are (for professionals) comparatively easy to follow.

The rules are usually given in the form of standards, codes, specifications and technical regulations. Some of the rules are intended to provide safety to users, the other are protecting the rights of customers or environment, while large number of rules is developed to simplify the life of manufacturers by providing mutual compatibility of products and enabling usage of standard machine elements like screws, belts and gears.

The design rules may be divided by the subject they cover. While some rules consider design of the specific machine elements or assemblies (like gears, bearings, drivers, pipes, pressure vessels, pumps, compressors, etc.), the other consider problems common to all mechanical systems like friction or vibrations. A critical place in mechanical engineering play rules of design that consider mechanical strength of the structures and components. For the reasons explained in the webpage “Dynamic strength for beginners“, the rules of design for the optimal static strength and the rules of design for the optimal dynamic strength are separately studied and defined.

As an example, let it be mentioned here that the consequence of the comprehensive scientific studies of the causes of crashes of the two “de Havilland Comet” airplanes was the simple design rule that the jet should have windows with rounded corners.

|

de Havilland Comet 1 with rectangular shaped windows, similar to the two aircrafts destroyed in the accidents |

de Havilland Comet 4 with circular windows |

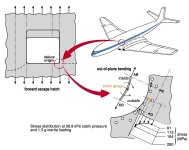

That simple rule contains within itself the results of many complex theoretical and experimental studies that revealed that the areas of the fuselage close to rectangular corners of the windows are extremely sensitive to dynamic loads and destined for a fatigue failure.

|

Theoretical analysis of the state of the “de Havilland Comet” fuselage close to the corners of rectangular windows |

Experimental proof of fatigue failure of the “de Havilland Comet” fuselage close to the corners of rectangular windows |